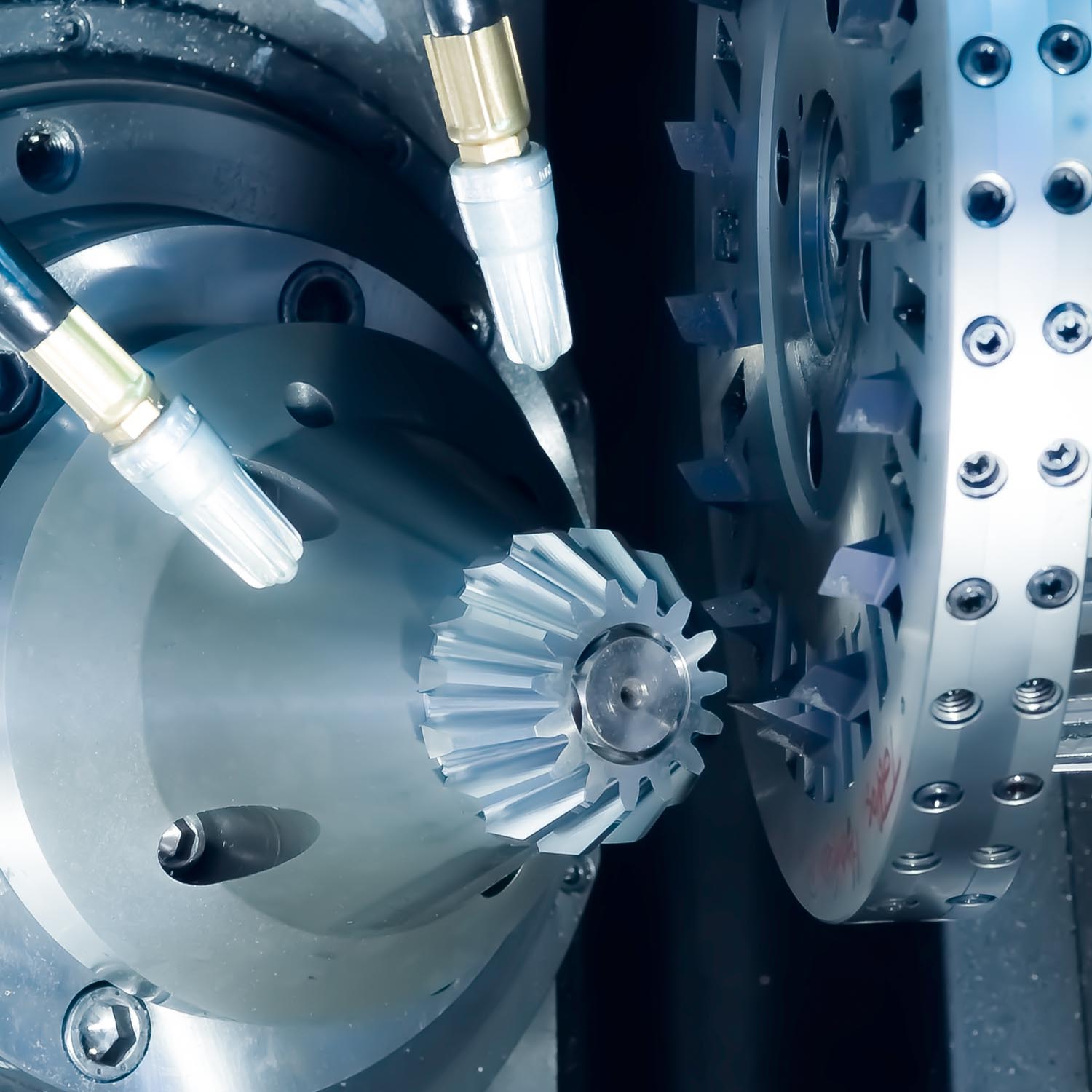

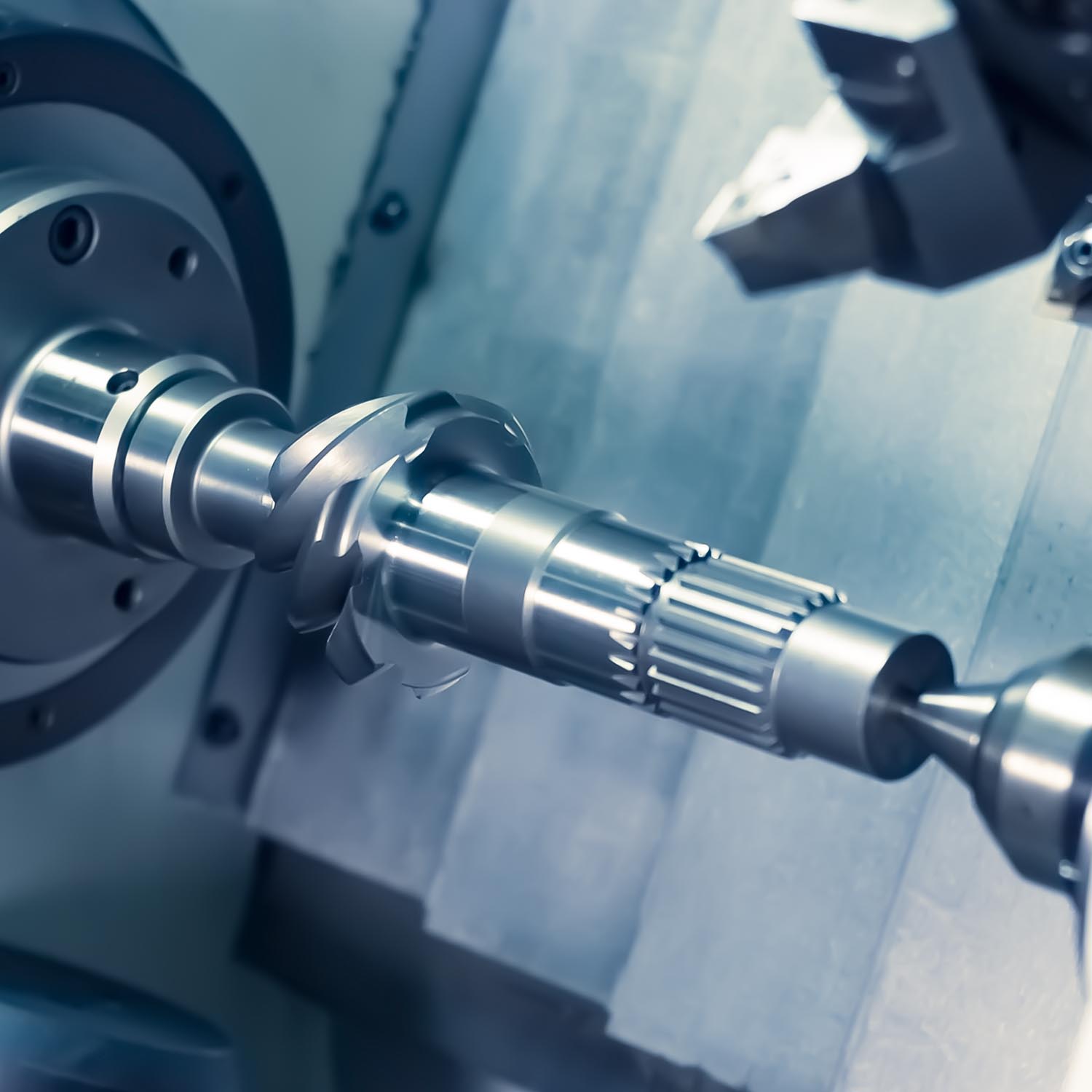

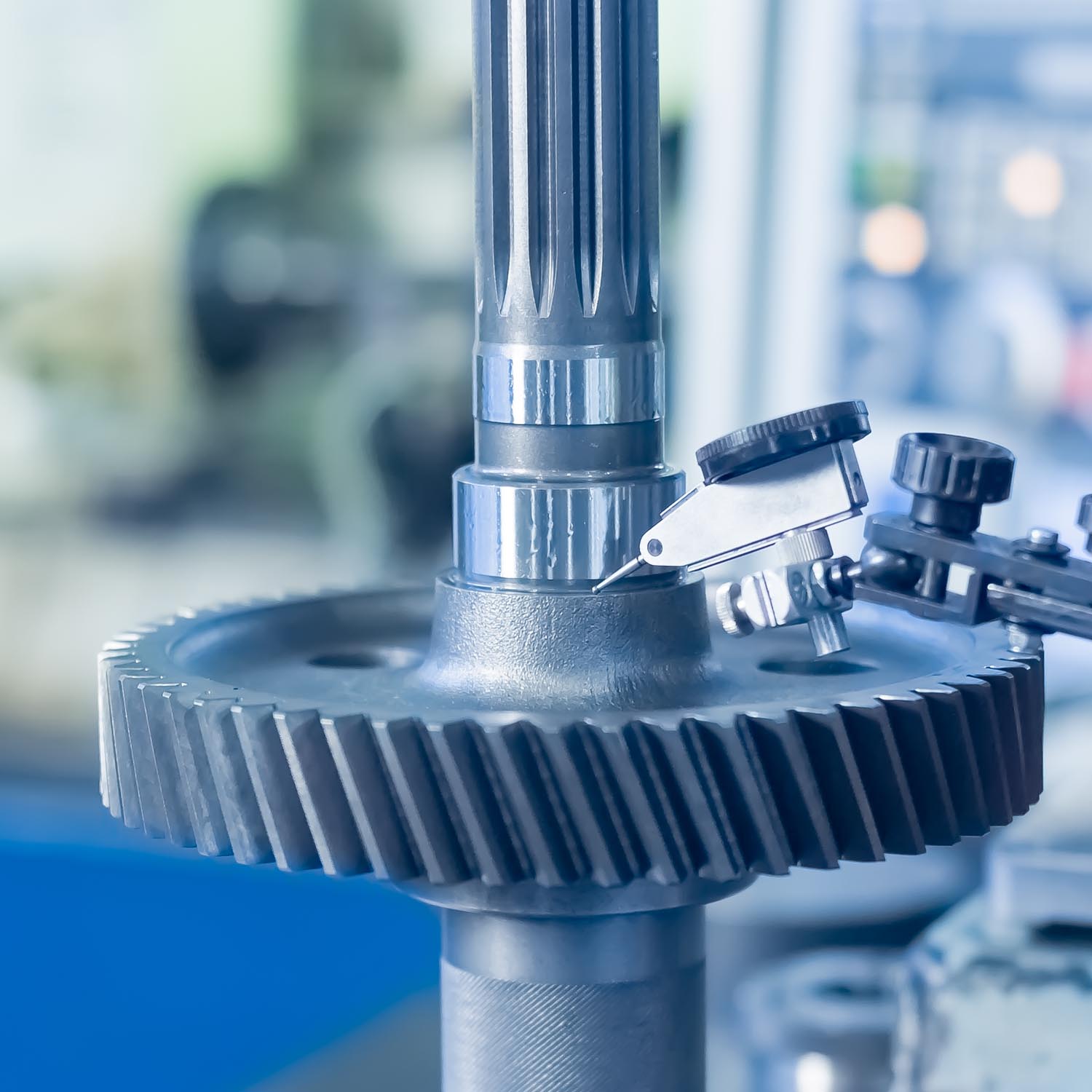

A FIRST-CLASS EQUIPMENT

TOFFAC INGRANNAGI’S production processes make use of the latest generation of CNC and robotized operating lines including: lathes and machining centres, broaching machines, gear hobbing machines, Gleason and Oerlikon spiral bevel gear hobbing machines, straight bevel gear hobbing machines, Power Skiving, gear shaving machines, tooth grinding machines, internal/external grinding machines, lapper, blade and tool grinding machines. State-of-the-art control systems such as the Klingelnberg P40, P65 and Gleason GMS 350, roundness gauges, Mahr profilometers, magnetoscope, 3D and optical measuring machine. A heat treatment plant and a highly equipped and qualified metallurgical laboratory complete the set-up.

MORE STRENGTH FOR THE FUTURE

In conclusion, the company is equipped with a complete in-house heat treatment service. One of the most modern and up-to-date plants built by IPSEN, is fully automated and approved by all customers. A well-equipped metallurgical laboratory managed by qualified personnel. A further step towards greater autonomy and an improved production capacity for the future.

CONTACT US

Toffac Ingranaggi S.p.A.

Via Vittorio Veneto, 113/115

35028 Piove di Sacco (PD)

Email: sales@toffac.com

Tel +39.049.9700188